Die-casting in Malaysia has become an essential element of the manufacturing industry, contributing significantly to industries like electronic, automotive, aerospace and consumer products. The process involves injecting molten metal into molds at high pressure to create complex and precise components that have little necessity for post-processing. The Malaysian manufacturing landscape has evolved quickly, as companies invest in state-of-the-art technology to enhance the effectiveness and quality of die-cast products. This has meant that the industry has become an important link in the global supply chain offering high-quality metal products for international markets. The government's initiatives to support the growth of industry and advancements in technology are further enhancing Malaysia's standing as a die-casting hub in Southeast Asia. A combination of highly skilled workers, robust infrastructure, and the strategic location have resulted in Malaysia an ideal location for businesses seeking to invest in die-casting manufacturing.

The automotive industry is one of the biggest producers of components made from die-cast in Malaysia and manufacturers depend on this process to produce critical vehicle parts. Aluminum and zinc die-cast components are extensively used in engine blocks, transmission housings, structural brackets and frames that are lightweight, contributing to general vehicle efficiency and performance. As the global automotive industry shifts towards electric vehicles, the demand for high-quality die-cast parts is increasing substantially. Malaysia's die-casting companies have adapted through the development of specialized components like battery casings, motor housings, and cooling systems specifically designed for electric and hybrid automobiles. Utilizing cutting-edge casting technology like vacuum die casting and high-pressure die casting, allows for that you can make high-strength and light-weight components that are essential to make modern cars. With Malaysia playing a key role in the global automotive distribution chain, locally-owned die-casting firms are continuously creating new products to meet the rigorous requirements of automakers worldwide.

Apart from automotive uses Die casting is an essential component of Malaysia's growing electronics industry. Demand for high-end components for consumer electronics, telecommunications as well as industrial applications has led to the development of die-casting facilities across the country. Electronic devices require metallic casings and heat sinks as well as intricate connectors each of which has to be produced with the highest quality to assure optimal efficiency. Malaysian companies have taken advantage of the latest techniques, such as vacuum die casting and semi-solid metal casting in order to eliminate failures and improve the quality of their product. The country's well-established electronics supply chain, combined with the country's access to global markets, has positioned Malaysian die-casting firms as trustworthy sources for global tech brands. As technology for 5G, smart devices, and Internet of Things applications continue to evolve, the demand for premium die-cast parts is expected to rise which will further fuel the industry's development.

Sustainability is now a major focus for Malaysia's die-casting industry and companies are actively adopting eco-friendly manufacturing techniques. Recycling and reusing metal materials, particularly zinc and aluminum have become common practices when it comes to die casting, which helps in reducing waste and conserving resources. A lot of manufacturers have adopted the most energy efficient melting and casting techniques to reduce carbon emissions as well as the overall consumption of energy. The shift toward environmentally sustainable manufacturing has spurred manufacturers to investigate greener casting methods including low-pressure die casting and gravity-based die casting that produces high-quality components with minimal production waste. The coatings and treatments used to enhance the durability and corrosion resistance of components made by die casting are being created using green components. With industries around the world pushing to create more sustainable supply chains, Malaysian die-casting firms are establishing themselves as the leaders in environmentally friendly metal casting, making sure they are competitive in the long run on the global market. To generate further details kindly look at www.senadiecasting.com.my/

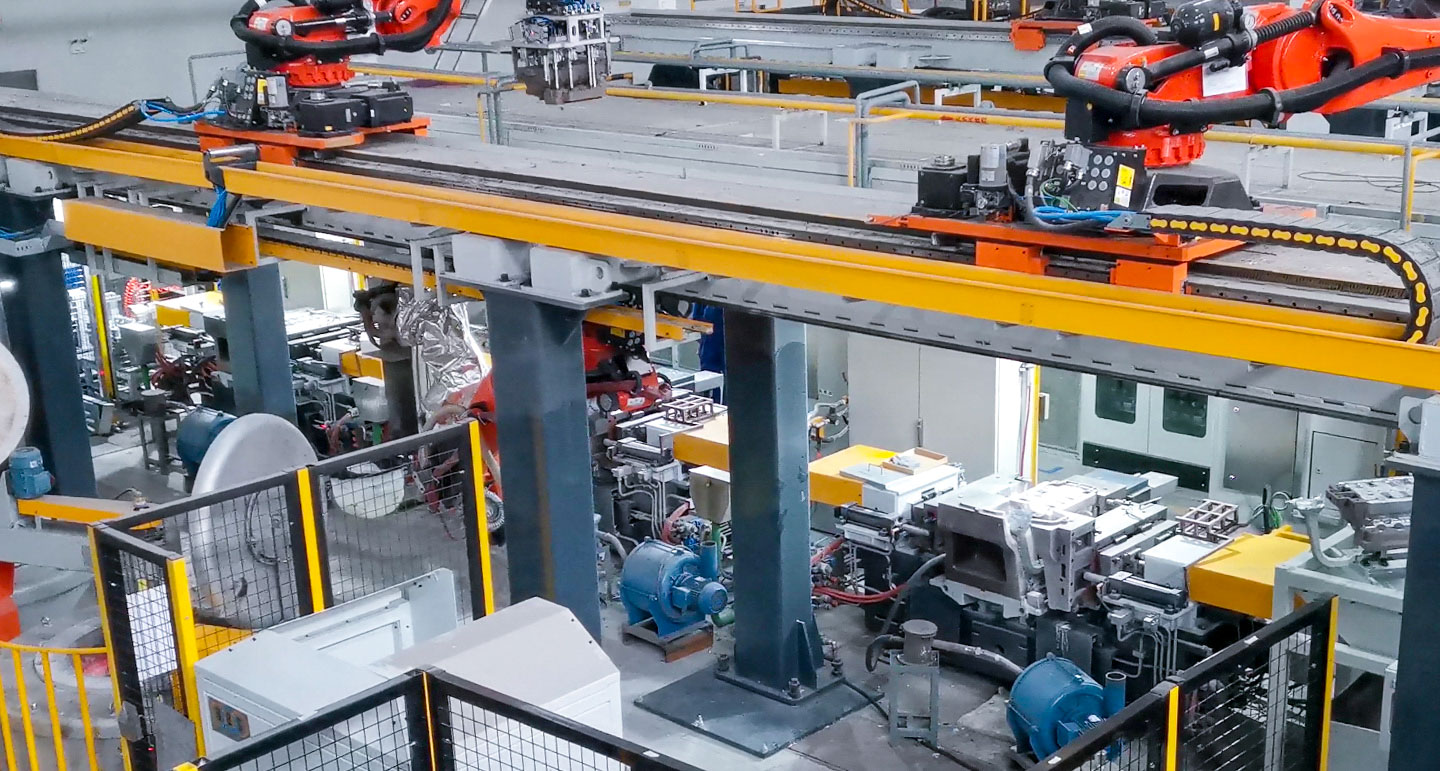

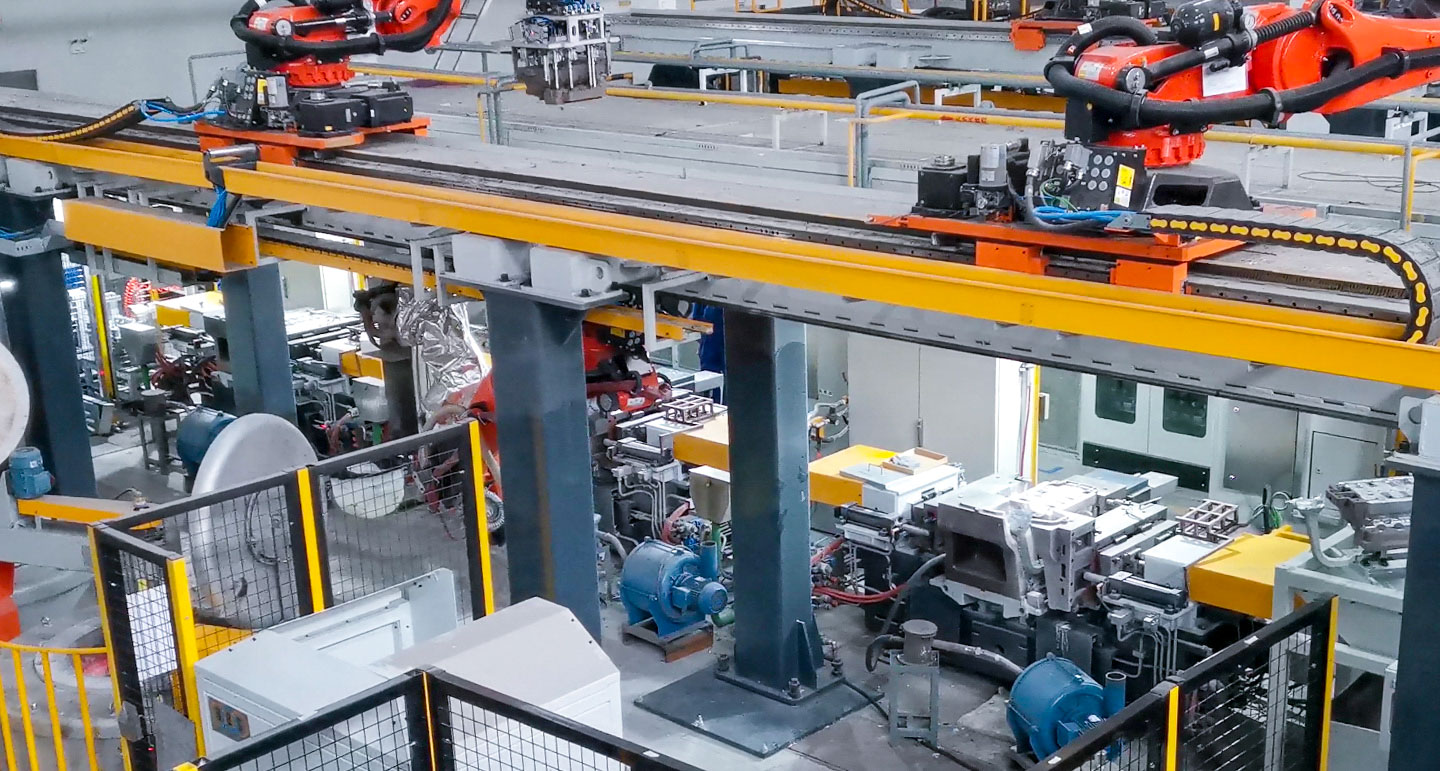

Continuous advancements in mold design and tooling has greatly enhanced the efficiency and quality of die-casting Malaysia. Quality molds are vital for making components that are free of defects, and companies have embraced computers-aided design as well as computer-aided manufacturing software to improve the precision of their molds. Simulation software lets engineers anticipate potential flaws and to optimize casting parameters before production begins, reducing material waste and ensuring consistency of the product. Robotics integration and automated molding process has also streamlined the manufacturing, which allows producers to make large amounts of components with minimal human involvement. These technological innovations have not only increased productivity but have also cut costs, making Malaysian die-casting firms better positioned in the international market. As industries demand higher accuracy and efficacy, continuing investing in mold design as well as the tooling process will be vital to continuing the expansion of the sector.

Die-casting in Malaysia is set to expand in the future as global demand for high-quality metal components continues to grow. The country's strategic location along with its highly skilled workforce and dedication to technology make it the leading manufacturing hub within the region. Firms that are embracing automated, artificial intelligence as well as data-driven manufacturing techniques will gain a competitive advantage by ensuring productivity and excellence. Due to increasing use in the electronic, automotive and aerospace Die-casting firms operating in Malaysia can enhance their capabilities and increase their position in the international market. Since sustainability is becoming a major priority, those who adopt sustainable practices and use energy efficient techniques will have a better chance of achieving further growth. The growth of the die casting business in Malaysia shows the commitment of the country to manufacturing with high precision, innovating as well as the development of its economy and establishing its position as a global pioneer in the field of metal casting.

Comments on “Die Casting in Malaysia: Advancing Precision Manufacturing”